Insights

Product Information Management and 3D Visualizations in Construction

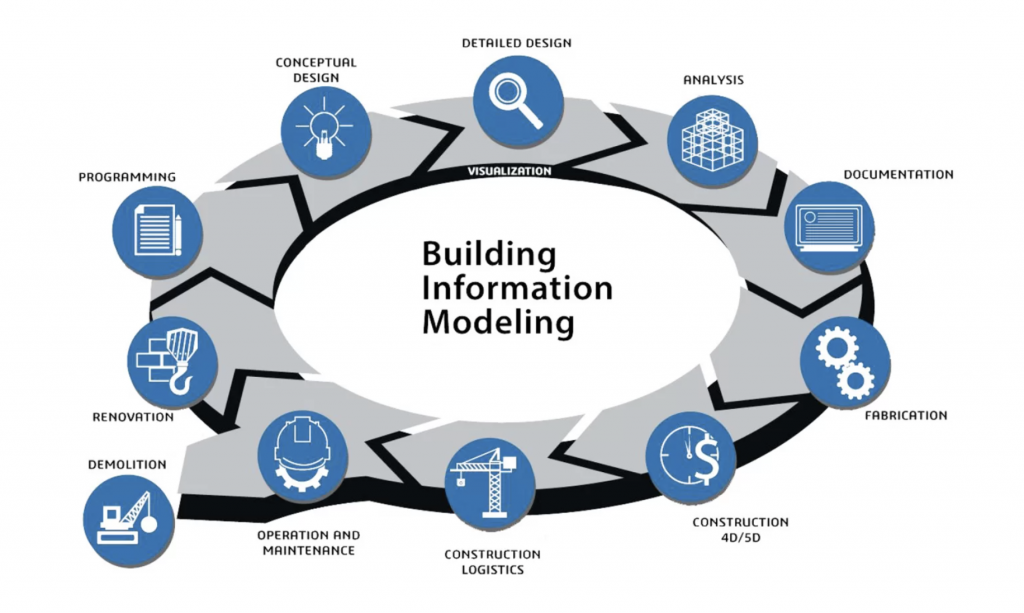

Building Installation Modeling (BIM) has been an important theme in the construction and installation industry for more than 10 years. The ambition is to create a digital twin of a building, a three-dimensional digital model of all physical and functional features of the building. The idea behind this is that this can lead to major benefits in all phases of the building’s life.

In the presales and preparatory phase, potential buyers and future users can use Virtual Reality (VR) techniques to get a lifelike representation of the building, which then only exists on a drawing. Dura Vermeer’s residential construction division has already gained experience with this. New homeowners get a lifelike impression of their future home with VR glasses, including possible options such as a dormer window, extension or kitchen layout. The customer is essentially buying “a living experience” and this tool proved to be very effective in the decision-making process. The choice stress decreases and customer satisfaction increases measurably (increase in the NPS by no less than 10 points). As a result, Dura Vermeer recorded a 60% increase in the sale of options. The use of VR even saved time and gave Dura Vermeer a better understanding of the needs of their customers.

In the implementation phase, a BIM model can lead to higher efficiency on construction and lower failure costs. With good 3D models of the components, it can be ensured in advance in the design that all components fit together and can work together functionally. Each component is placed in the 3D design to ensure that everything fits and is accessible within the available space. The importance of this in installation technology is increasing, because due to increasing requirements of legislation and regulations and users, these installations are becoming increasingly complex and extensive.

A BIM model is also of great value during the operational phase of a building. The performance and maintenance history of components can be continuously monitored. This means that (preventive) maintenance can be properly planned. The origin and composition of components that are replaced is known, so that they can be reused, overhauled, recycled or disposed of in a sustainable manner. More and more clients, such as the Government Buildings Agency, are therefore including requirements with regard to a digital construction file in their specifications.

The developments do not stand still either. BIM modeling offers interesting commercial opportunities for builders such as Dura Vermeer. For example, Dura Vermeer could develop a VR platform where partners can offer products such as kitchens, furniture or even garden design. This can even lead to custom 3D printed products, such as a unique flower pot or lamp that fits exactly in your living room.

For the management and maintenance of buildings, experiments are being done with Augmented Reality (AR) and Mixed Reality (MR) techniques. On location, a technician with VR glasses can see exactly how a new part should be connected in an installation.

All this also places new demands on organizations. Digital Twins and VR techniques offer more room for individual freedom of choice and customization in construction. The processes and the organization at the builder must be adapted to this, so that, for example, real-time customer wishes can be made visible in the design. A platform model requires different contract forms with suppliers and customers, with room for multiple delivery times for different partners. The entire organization will have to think in a more customer- and user-oriented way.

The developments also lead to a greater need for product data, such as accurate and reliable 3D models. This has long held back developments, because there was no common standard. Each 3D design program had its own specifications. This has changed in recent years. The Dutch construction and installation sector is developing a Uniform Object Library (UOB) within ETIM. In this library a uniform three-dimensional model is made for each ETIM product class. The product is defined with a number of standardized parameters, such as length, width, height and position and diameter of connections for a pump. When the model is ready for a product class, affiliated manufacturers publish the parameters for their products on the 2BA data pool. Any design or visualization software can use these UOB objects to create a three-dimensional representation.

In addition, there is a general trend towards more high-quality product data, such as article relations (alternatives, accessories), photos, videos, 360° images, certificates and manuals. This data is exchanged via an increasing number of different portals and marketplaces, such as GS1, 2BA, Amazon, Channable and World of Content.

Conclusion

The market for three-dimensional product visualizations is developing rapidly. The possibilities are great and this also makes great demands on the suppliers of the required data. The organization must be able to respond to this. It is therefore very important to have a PIM/MDM solution that is scalable and flexible to grow with these developments. Squadra has extensive experience with the selection and design of these systems and can help you with this.