Cases

Vistaprint

- Forecast model consumption levels

- 500 – 600 unique SKU’s

- Location Venlo

Vistaprint, part of Cimpress, supports small business owners with contemporary, tailored marketing solutions. The company offers a wide array of print marketing products, including business cards, stickers, and apparel. These items are dispatched from various storage sites, specifically the facility located in Venlo, Netherlands.

Challenge

Vistaprint’s Venlo storage facility features a diverse inventory of 500 to 600 unique SKUs. To prevent stock shortages, Vistaprint aims to forecast SKU consumption accurately. With this capability, they can plan for the next six months; this is crucial given that many SKUs are produced by Chinese suppliers, resulting in longer lead times.

Certain seasonal spikes, such as those for Christmas-related products, are relatively straightforward to predict. However, Vistaprint has found that predictions from their marketing team are often imprecise and insufficiently detailed to effectively anticipate market demands.

To address this, Vistaprint enlisted Squadra to devise an AI-driven solution to generate accurate and comprehensive forecasts. This initiative was initially tested at the Venlo site, with plans for potential rollout to additional locations in the future.

Solution

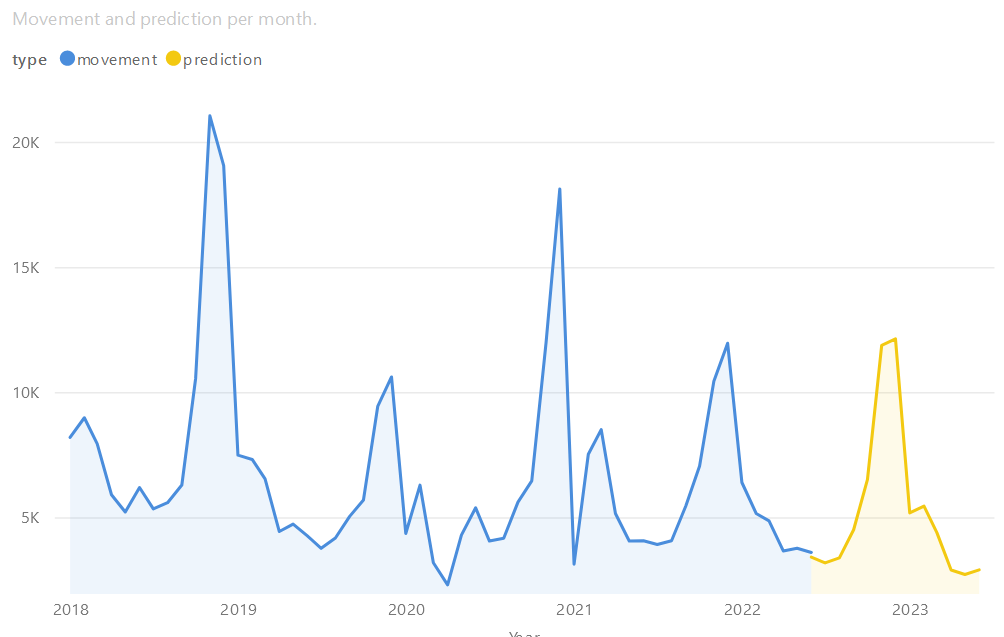

Squadra: Machine Learning Company created a software tool incorporating a forecast model to estimate consumption levels for Vistaprint Venlo. The model leverages data collected over the last four years. By analyzing historical data, the software identifies patterns and makes future projections based on these trends.

Each week, Vistaprint provides updated data, allowing our software to generate predictions. Vistaprint can access this information and trend graphs via a dashboard, and we also send out weekly alerts featuring predictions and updates based on new data.

Result

As a result of this initiative, Vistaprint Venlo now possesses a precise and comprehensive understanding of future trends in their SKU usage. This enables them to be well-prepared for upcoming market demands, ensuring they maintain adequate stock levels and have ample time for orders from Chinese suppliers. The project remains in progress, with future steps potentially including the development of an application that can help Vistaprint monitor stock levels and an expansion to other facilities.

Do you see potential for your business? Reach out to us at machine-learning-company.nl !