Cases

Global paint brand

This paint brand is active in over 70 countries around the world and is engaged in coatings designed for automotive, architectural, marine, aerospace and many other purposes. The organization employs over 40.000 people and generates over 15 billion dollars in revenues annually.

Recently, the organization faced the shift from the traditional sales channels to online both directly and indirectly through the wholesalers and retailers worldwide. And in all these countries, markets and channels, there is a growing demand for product data. Customers and consumers demand high quality, rich data including product images, technical data sheets and safety data in time and on demand. This was a major challenge with hundreds of brands.

The decision

In 2016 the organization decided to implement a PIM solution. The objective was to collect, enrich and distribute product data in all EMEA countries from one solution. The main driver was to not to just deliver the content, but to make sure the quality of the data is guaranteed before it leaves the organization. The organization has high quality standards and it has to ensure that all data distributed adheres to its standards.

The channels to be supported were both B2B as well as B2C including websites and webshops. And in some countries like in the Netherlands, there was a demand to deliver the product data to customers using the GS1 datapool. In other words, a challenging environment to kick-off such a project.

Initially Squadra was selected to support the organization with the vendor selection phase. The requirements were enormous. Thousands of products each with up to dozens of articles for many brands, in many countries, languages and channels can only be handled by the best of breed among the PIM systems. With the help of Squadra, the organization managed to narrow down the number of options and finally selected the PIM system to meet the challenge.

The next step was to select a technical consultancy company to set up the system. Next to this technical partner, Squadra was selected to run the program together with a dedicated team of internal employees. The focus areas were split into organization, data, processes and IT. Each with an internal responsible employee to chair the focus area. The business was aligned and Involved from day one. Not only as initiator of the project, but also to support it with capacity and market knowledge. Technical, logistical, marketing and other teams were involved to define the product data requirements. This resulted in a complete data model for all required product information in the different channels

One step at a time

From the project kick-off in 2017 the implementation accelerated into 2018 with the delivery of the first operational milestones. The content delivery to the websites of paint brands was streamlined using the PIM. And in early 2019, after a period of substantial testing, one of the Dutch retailers announced that our client was connected as supplier through the GS1 Datapool using the extended dataset as defined for the Dutch DIY market. This may sound “normal” but given the number of specific attributes related to a product like paint, this was definitely a major accomplishment for all parties involved.

Crawl, walk, run…

Throughout 2019 the project really got up to speed. The number of supported countries grew, and the assortment grew rapidly with the decision to also support non-paint products which are sold on the web shops in combination with paint. For example, brushes, tapes, rollers etc. But also ladders, scaffolds, overalls and many more articles. Everything a professional painter needs to do the job.

This resulted in a new challenge. For paint, our client is responsible for the creation of the data itself. But for non-paint, there is a strong dependence on the suppliers for the supply of product data. For non-paint products, the organization worked together with another datapool called EZ-Base in which the data of several hundreds of thousands of products is already collected. And the collaboration between these two companies worked bi-directional. The data for paint products to be stored in EZ-Base is now supplied through our clients PIM as well.

Having tackled the non-paint challenge, the next opportunity came along. The organization is obliged to supply Technical Data Sheets to professional users. In these data sheets the professional painter will find very detailed instructions on how to prepare the surface to be painted and which coatings in which order need to be applied to deliver a specific end result. The sheets have data on the substances used, the drying times, the thickness of the layers and much more. The creation of these data sheets is time consuming and very precise.

Ingenuity

The PIM came to the rescue. By adding some specific fields to the PIM and through combining and reformatting existing data, the data sheets can be produced using the PIM in a ready to distribute PDF format that is automatically placed on an external blob storage together with the image material of the product itself. And the link to the sheet is published from the PIM.

If you think the data sheet production was a clever idea, read the next part. The PIM team was facing a rapidly growing internal demand to support new brand sites and web shops in more and more countries. But it was not intended to have the PIM team grow with the demand. Something better needed to be added. And thus, the idea of the PIM Proxy was born.

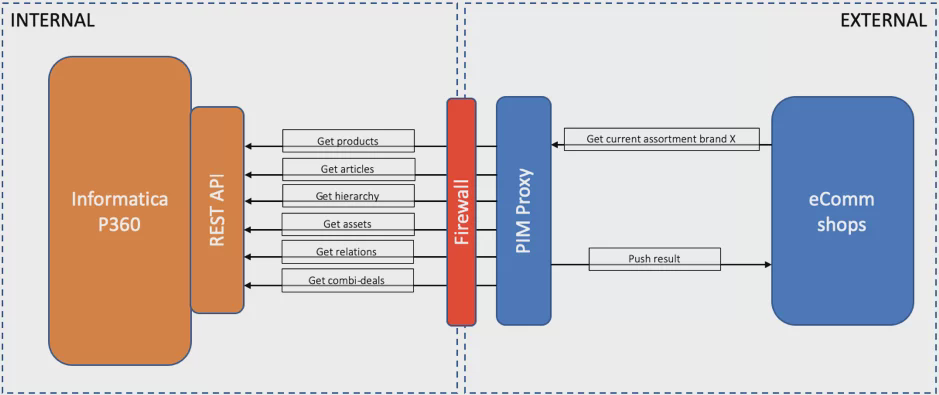

A technical team of the internal IT department designed and built a ‘proxy’ that translates the complex API functionality of the PIM itself into an easy to use, well documented and secured set of interface calls. This set can be used by the many digital teams involved in the creation of the organizational sites. A website can for example call the PIM Proxy asking for all updated items since yesterday. The proxy will translate this into a number of interactions with the PIM and as a result it delivers one simple update feed in return.

The benefit of this approach is that today a country or business unit can prepare the data autonomously in the PIM and the local digital team can build new websites using the PIM even without ever consulting the PIM team!

The image below shows how the PIM proxy works. Let’s say a business unit from a certain country has to develop a web shop. This business unit can access data about the current assortment from the internal PIM system. The proxy uses an API (a technical protocol) that allows the transfer of data. If for example the business unit wants to gather information about the assortment of a certain brand, the proxy will translate this question into multiple smaller questions (asking information about products, articles, hierarchy, assets, etcetera). All of these answers are combined in one simple answer and send back to the website of the business unit. This way, a relatively small PIM team can support multiple web shop initiatives.

What’s next?

The corona pandemic in 2020 had its effects on the PIM project as well. Surely the team had to work remotely on the continuation of the project, but the pandemic itself had an effect on the business. In divisions like automotive the demand for paint dropped significantly. But for architectural coatings, the demand grew and specifically in the area of the online sales. The PIM project turned out to deliver as planned to support the business throughout this difficult period of time.

Squadra has been involved in the project since the start actively supporting the business to take maximum advantage of the organizations investment in a comprehensive tool like the PIM system. Furthermore, Squadra has helped structuring the processes surrounding the PIM to enable countries to easily request changes or new projects in the area of PIM and implement them accordingly.